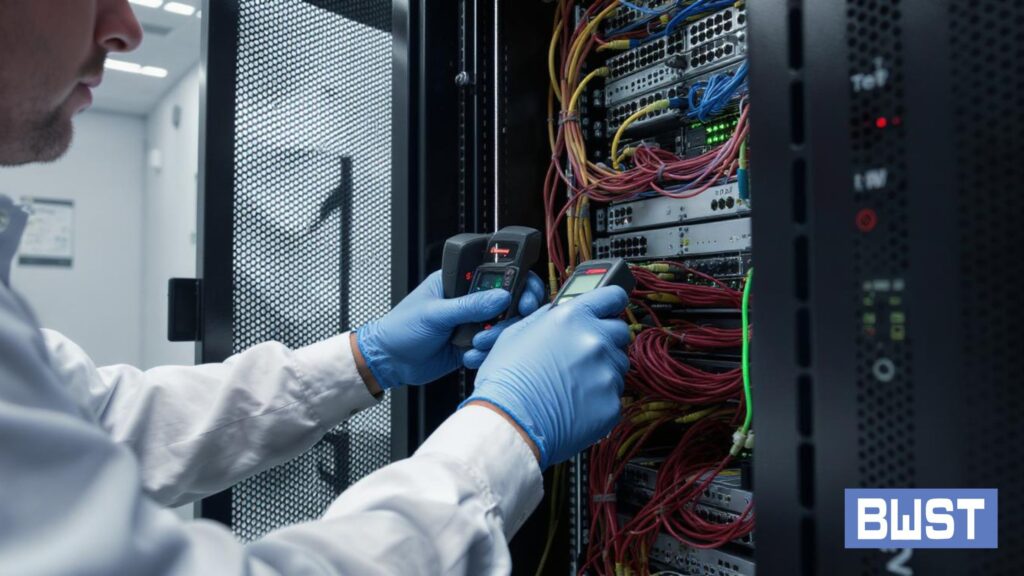

Engineer testing PDU in real rack simulation environment.

Introduction

Most customers see the finished product — a powered-up iPDU in a live rack, a 10G SFP streaming data across continents, or a sleek enterprise router humming quietly.

But what they don’t see is the journey before the label goes on. At BW Solution Tech, our gear doesn’t just go from shelf to shipping box.

It goes through 12 rigorous, benchmarked, and repeatable steps — each engineered to validate performance, compatibility, and resilience. Because hardware failure isn’t just a technical issue. It’s a risk to your uptime, your deployment timeline, and ultimately, your reputation.

Why QA Matters More in 2025 Than Ever

In 2025, the expectations for data center performance have never been higher:

- Uptime is a non-negotiable SLA — even at the edge.

- Remote infrastructure now supports real-time applications from AI training to industrial IoT.

- Scaling complexity demands plug-and-play gear that just works, from Day 1.

In short, failure is not an option. That’s why our QA isn’t just a formality — it’s an essential guarantee.

Our 12-Point Testing Framework

We believe you should trust your gear not because we say so — but because we tested it like it was going into our own rack.

Thermal Stress Testing

Using IR thermal sensors, each unit is exposed to elevated temperatures (up to 55°C/131°F) under load, to simulate real rack heat conditions.

We analyze for component warping, signal drift, and thermally induced latency.

Continuous Power-Load Cycling (for iPDUs)

Our intelligent PDUs are subjected to on/off power cycling under varying loads across all outlets, simulating weekend load swings, brownouts, and failovers.

Port Signal Integrity Test (for 10G SFPs, Routers)

We use Bit Error Rate Testers (BERTs) to ensure signal clarity under stress and verify that all transceivers transmit and receive within allowed thresholds.

Compatibility Validation

Our gear is tested on:

- Cisco Nexus & Catalyst

- Ubiquiti UniFi switches

- HP Aruba platforms

We verify handshake protocols, LED indicators, CLI interface compatibility, and hot-swap behavior.

Live Rack Simulations

Before final dispatch, every unit is mounted into a live rack environment and run in typical deployment configurations for 6–12 hours, monitoring:

- Power stability

- Port uptime

- Error rates

- Heat dissipation

How This Impacts You

When you order from BW, you’re not buying from a warehouse — you’re sourcing gear from a lab-tested workflow designed for:

✅ Lower failure rates on arrival

✅ Faster plug-and-play deployment

✅ Fewer compatibility surprises

✅ Peace of mind at scale

Testimonial:

“We used to factor in a 5–7% fail/return rate with new hardware. After switching to BW for our critical components, that’s dropped below 1%. Their QA is the real differentiator.”

— Neel Roy, Infra Lead, NexSite Global

Conclusion

We know that when our equipment fails, your infrastructure takes the hit. That’s why we test it like it’s ours — and we’ve engineered our QA process to filter out the silent killers of enterprise reliability: thermal failure, signal noise, firmware mismatches, and overlooked corner cases.

Hardware failure isn’t just a hassle — it’s a risk to your reputation. That’s why we test like it’s our data center.

👉 Ask for our QA checklist. Let’s build reliability together.

Internal Links:

Call to Action :

Call us : +91 7439814118

Email us :